Murr, Germany. An aqueous base, different tack properties, limited tendency to yellowing – Curvalin D 409X from ZELU CHEMIE GmbH is a product series consisting of water-based pressure-sensitive adhesives (PSA) with an already proven track record. That makes the products the ideal solution for a wide range of self-adhesive applications, from adhesive tapes to self-adhesive films. The products can be readily integrated into production processes – a particular strength compared to hot-melt adhesives – and their differing properties, such as their ability to debond and their tack, can be individually adapted.

Zelu’s Curvalin D 409X series dispersion adhesives enable bonding without the use of organic solvents. As a result, they contain only low levels of volatile organic compounds (VOCs), thereby eliminating health hazards for production workers.

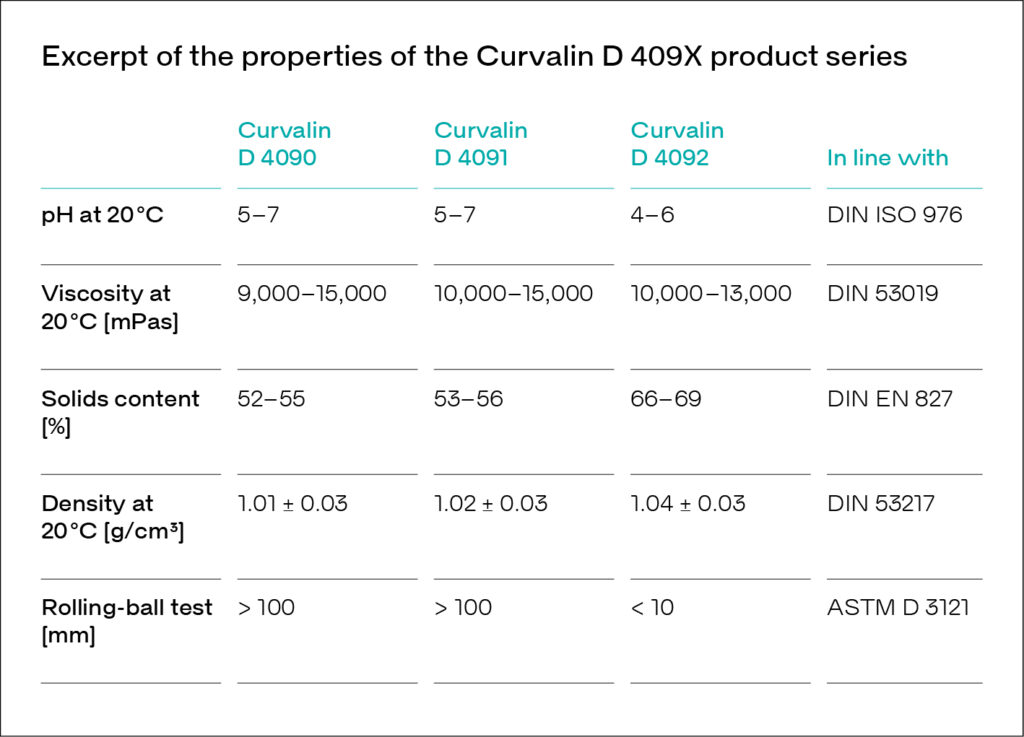

It also means that process times can be minimised, as pressure-sensitive adhesives contain around 50 to 70 percent solids, as shown in the following table.

In addition, the products have different tack values for permanent and non-permanent applications, as evidenced by the results of the rolling-ball test (see table). For the two non-permanent adhesives Curvalin D 4090 and Curvalin D 4091 the ball travels more than 100 mm, meaning their tack values are low and debonding is easy. In contrast, the tack value of Curvalin D 4092 is much higher, and hence it is suitable for applications requiring permanent adhesion. It can also securely bond to a variety of substrates, such as plastic, glass or metal.

In their processed state, the products are resistant to various weather conditions such as temperature, humidity or UV radiation. They are also virtually free from yellowing and, depending on the type selected, can be removed without residue.

Advantages in use compared to hot melts

When using Curvalin water-based pressure-sensitive adhesives no energy-intensive melting is required. Their use at room temperature eliminates the risk of burns for production workers and reduces the complexity of production lines.

In addition, the products are easy to integrate into existing processes and can be applied using classic mechanical or automated processes such as spraying, rolling or film coating, thereby lowering investment costs for plant technology.

Product development driven by many years of expertise

Zelu’s many years of expertise in hot-melt adhesives, however, stood it in good stead in developing Curvalin D 409X, for instance in adjusting the desired level of tack.

In addition to the previously mentioned adhesive tape and self-adhesive film applications, the product series could also be used in the future to manufacture insulating mats, sound insulation, skirting boards, floor heating elements, labels and other self-adhesive products.

Bildquelle: © Иван Решетников – stock.adobe.com