Ostfildern-Kemnat, Germany. Whether it’s for automotive head-lights, in greenhouses or for offices and homes, LEDs have gained acceptance in almost all fields of lighting applications. This is because in addition to their low energy consumption, LEDs are also very versatile. However, this often requires integrating additional electrical and electronic components into the LED luminaires. For this purpose, WEVO-CHEMIE GmbH offers tailor-made potting compounds, gels, adhesives and sealants that also satisfy additional requirements such as protection against environmental influences, heat and chemicals.

The demands on lighting are manifold and nowadays go far beyond classical aspects such as safety. Among other things, factors like easy adaptability to ambient conditions, integration into smart applications or the technical possibilities for further development play an important role. State-of-the-art lighting systems, for example, can precisely create the mood people are looking for – whether they are at home, at work or in their car. In greenhouses, plant growth is promoted by creating lighting conditions with specific wavelengths (“horticultural lighting”). On the roads, intelligent lighting systems automatically adapt to approaching vehicles or pedestrians.

Technically, this means that LEDs and electronic components need to be integrated into the luminaire and protected against environmental influences in order to guarantee a long service life. In addition, electrical insulation is another important aspect essential to protect users and electricians from hazards and to avoid short circuits and fires. The development of smart and networked systems, as well as new technologies such as Li-Fi (light fidelity), also demands additional components, including sensors, antennas, transformers, drivers and IoT devices. These are increasingly being integrated directly into the luminaire itself rather than realised as an external component.

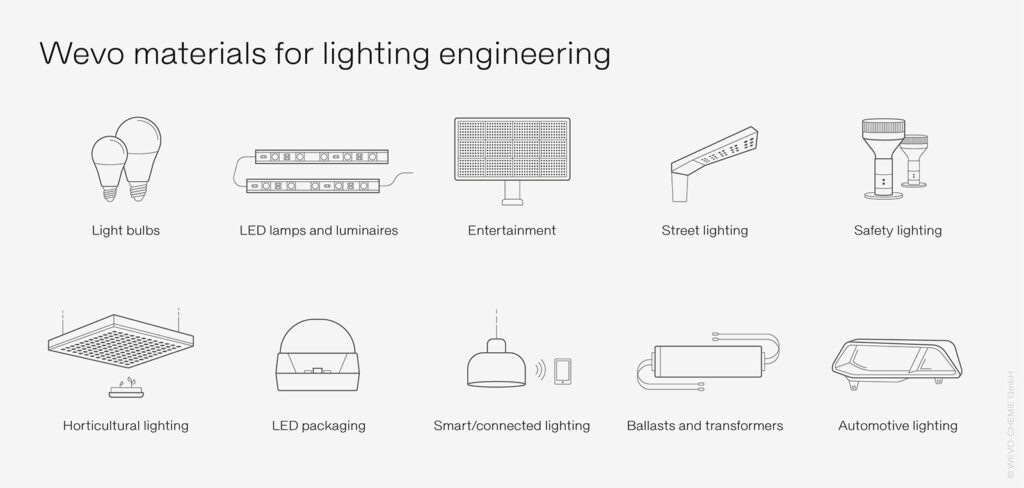

With its tailor-made materials based on polyurethane and silicone, Wevo is actively facilitating these developments in LED lighting systems – and the products can be used in a wide variety of applications (Fig. 1).

Regardless of the application, the use of potting compounds, adhesives and sealants brings benefits in terms of design, the manufacturing process and product longevity, and solves among other things the following challenges that arise with respect to lighting engineering.

Challenge: environmental conditions

Potting compounds, gels, adhesives and sealants from Wevo can be used both indoors and outdoors. Thanks to special ingredients used in their production, LED luminaires (including LED strips) are reliably protected against environmental influences such as ultraviolet light, humidity, dust or corrosive gases. The materials, which are based on polyurethane and silicone, can be used for interior luminaires as well as for street lamps, architectural lighting or illuminated advertising systems.

When light sources are used in hazardous or safety-critical environments, such as chemical plants, tunnels or airports, they are subject to high requirements in terms of resistance to a wide range of environmental conditions. These include, for example, chemicals, explosive gases, salt, weather or insects. The use of hydrolysis-resistant and hydrophobic polyols with low hygroscopicity and special UV-resistant isocyanates in the hardener component ensures both reliable protection and electrical insulation even in such cases.

Challenge: fogging

For use in automotive headlamps and rear lights, Wevo has developed special adhesives and sealants that prevent both tension-cracks in the housings as well as fogging. To achieve this, the compatibility of the materials with amorphous plastics such as PC and PMMA was adjusted. In addition, they consist of particularly pure and solvent-free raw materials.

Challenge: operating temperatures

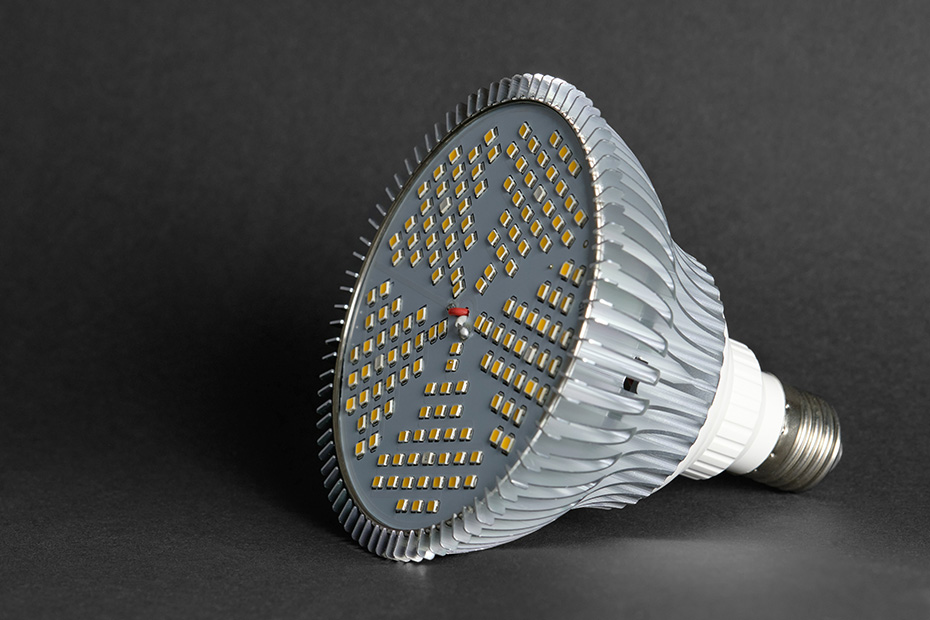

Another challenge are high operating temperatures, as in the case of high-power LED spotlights for theatre stages and closely packed LED luminaires for greenhouse lighting. In these cases, the special heat-conducting potting compounds and gap fillers provide reliable protection for the components and LEDs. Effective heat dissipation from the LED modules to the heat sink and ultimately to the ambient air is ensured by the use of special thermally conductive fillers in the potting compound or thermally conductive paste.

Wevo’s latest brochure on “Lighting” provides lighting system developers and designers with a comprehensive guide that enables them to select the right product for their applications. You can download it here.

Image source: © Aleksandr – stock.adobe.com