Murr, Germany. A number of chemical raw materials are currently subject to fluctuations regarding availability. For many in the industry, this is resulting in supply problems or even production being halted. As a result, ZELU CHEMIE GmbH has switched its “Zelukleber P 49XX” product series to an alternative raw material base that has so far offered a reliable supply. At the same time, the solvent content of these adhesives has been significantly reduced by increasing the solids content to a level of up to 74 per cent. The low solution viscosity facilitates easy processing and problem-free integration into existing production processes for almost all types of bond in the upholstery sector.

Solvent-based adhesives continue to be widely used in the upholstery industry thanks to their easy application, reliable production process and cost-effectiveness. However, the demands with respect to lowering emissions and optimizing workplace safety in production are growing. In addition, the availability of some raw materials needed for the manufacture of many conventional products is currently limited – particularly materials for polychloroprene-based aqueous dispersion adhesives –, which is why alternative adhesive systems are becoming increasingly relevant.

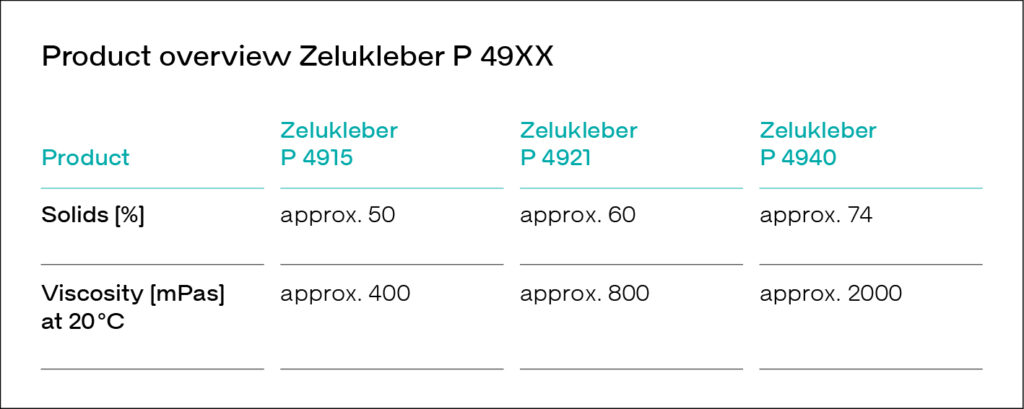

With Zelukleber P 49XX, Zelu has developed a product series that currently features solids levels of up to 74 per cent – while greatly reducing the solvent content at the same time. An overview of the products is provided in Figure 1.

Almost all types of bond in the upholstered furniture sector are possible with Zelukleber products, including ones involving complex geometries, large dimensions and high-tension bonds, in combination with high heat levels. What’s more, the switch to appropriate raw materials has so far allowed us to ensure reliable supplies, despite the ongoing raw-material shortages.

During product development, special attention was paid to securing a low dissolving viscosity, so that the adhesives can be deployed in existing pump systems quickly and easily despite their high solids content. Their good handling properties have been verified many times over in reference applications and serial production all around Europe.

Zelukleber products unite the advantages of a product range that has been built and optimized over decades in just a few variants: they offer both high initial and final strengths, solutions for a very long wet life on large bonding areas and the famed “Zelu tack”. Besides that, the low solvent content evaporates quickly during application and reduces potential fire risks. This assures a reliable, safe production process with a high-quality end result and long-term adhesive strength.

More information: Website ZELU CHEMIE.

Image source: © Ilya Zaytsev – stock.adobe.com