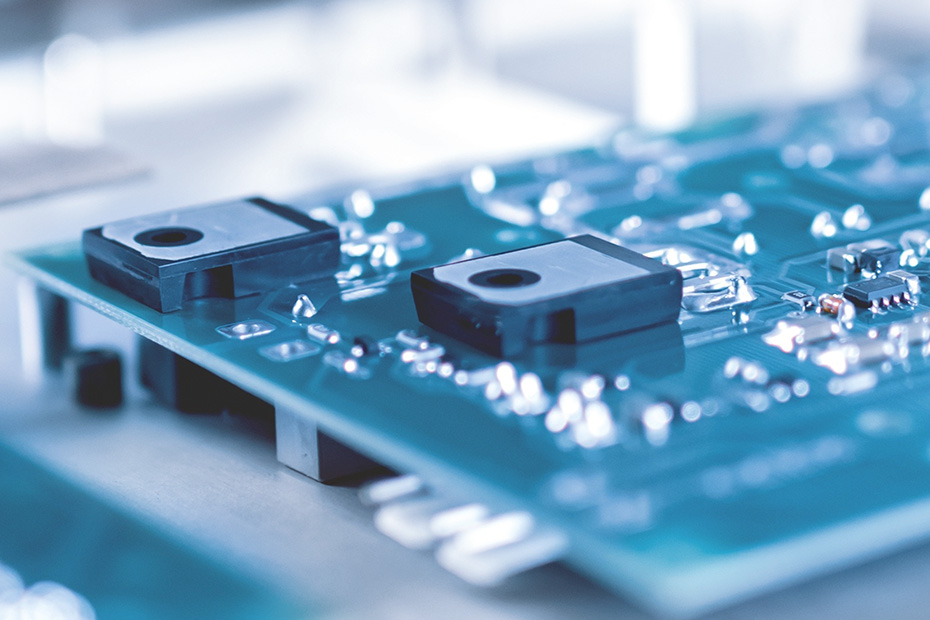

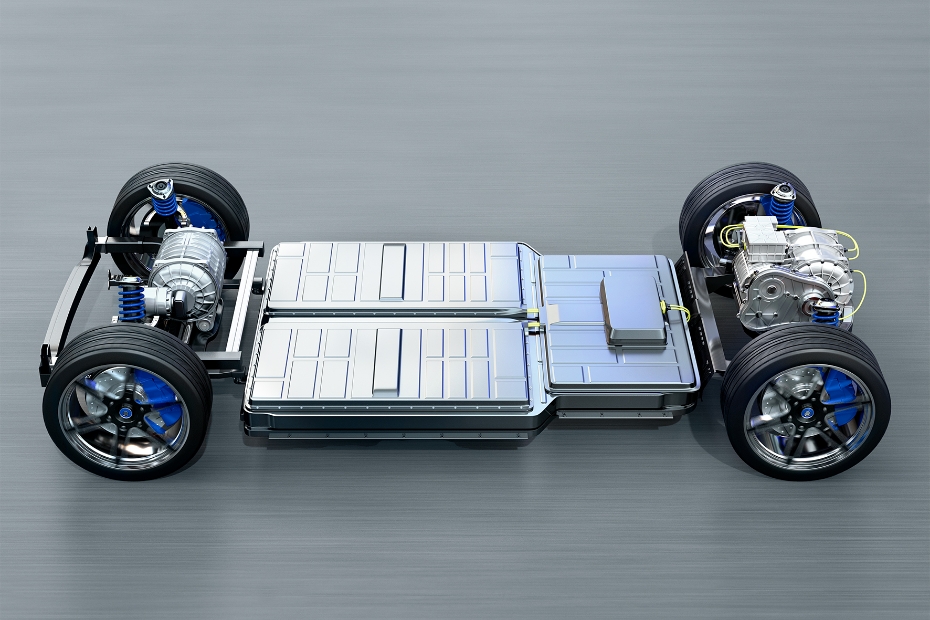

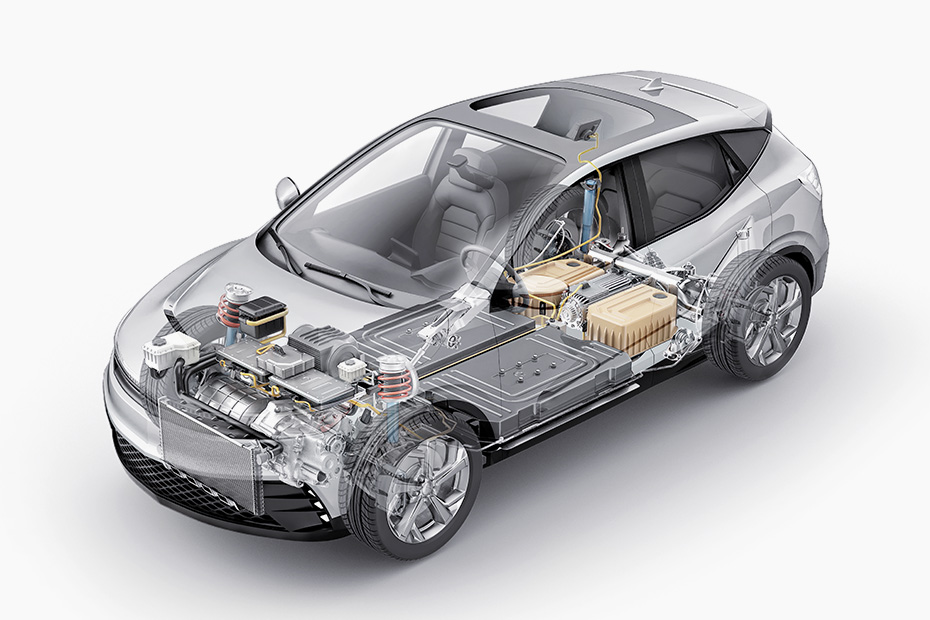

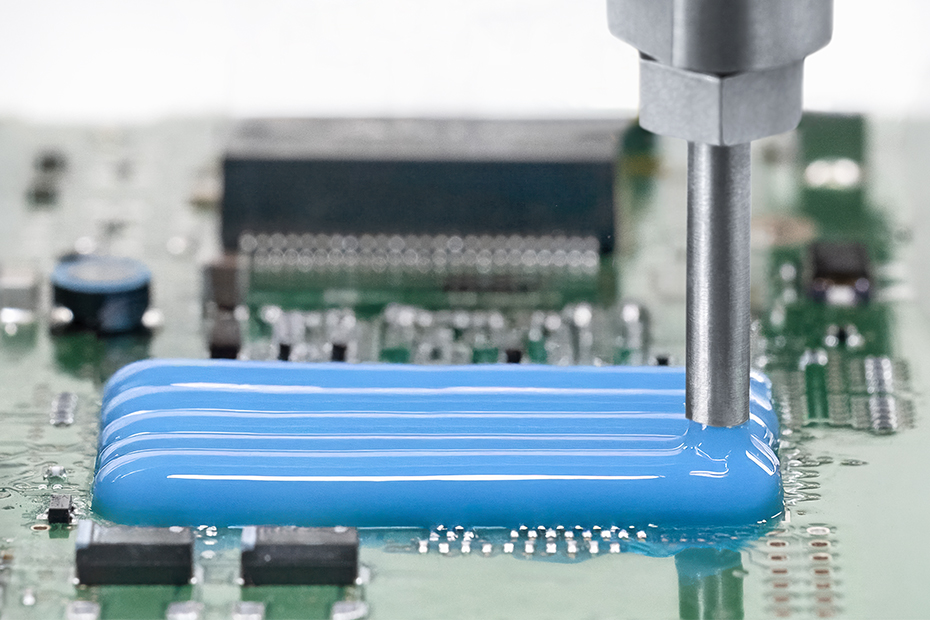

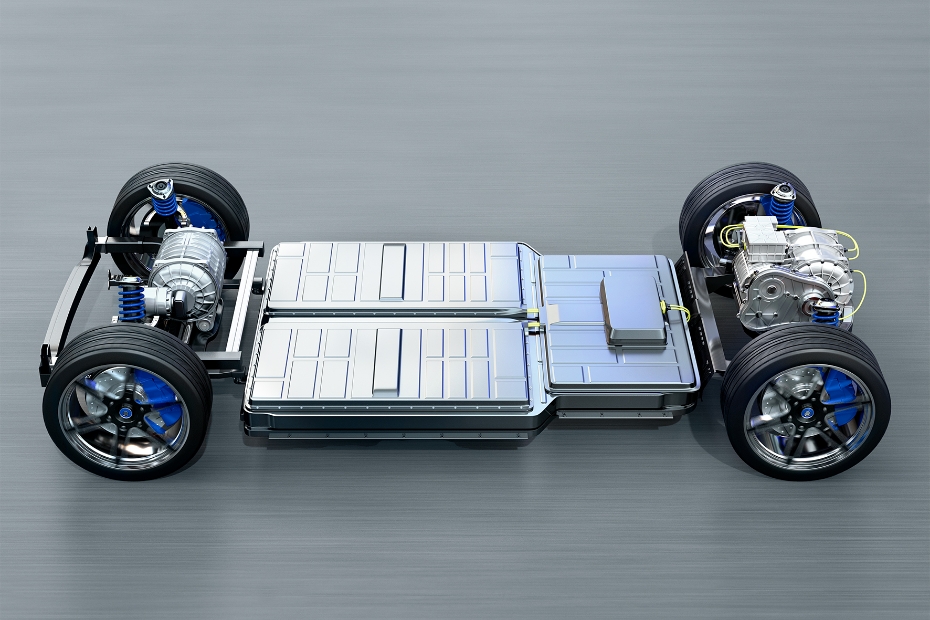

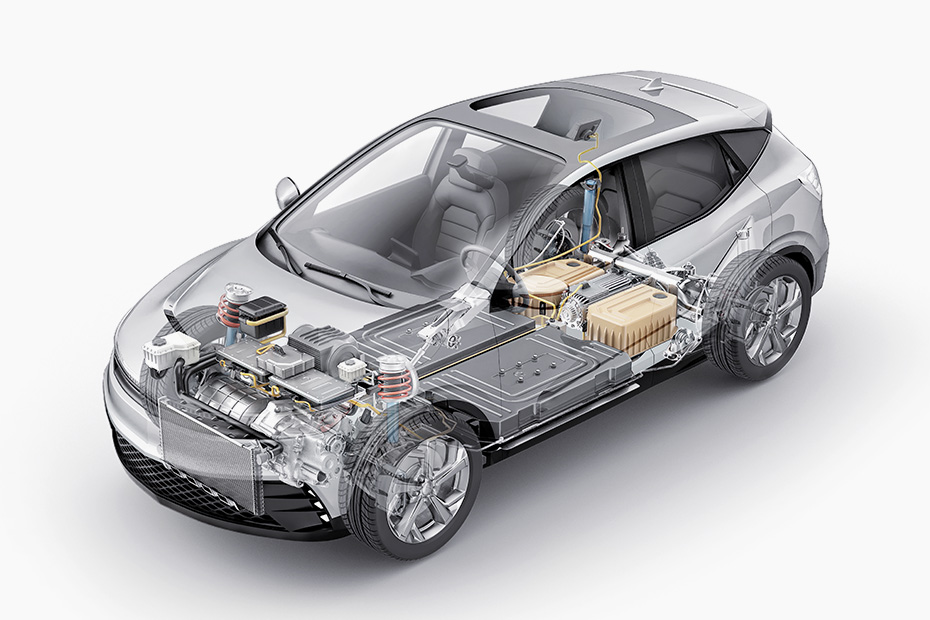

Power electronics in electric vehicles place high thermal and mechanical demands on 2K silicone potting compounds.

The WEVOSIL 2210x FL product range comprises high-performance 2K silicone potting compounds for automotive power electronics. They enable efficient thermal management, electrical insulation and mechanical decoupling of DC/DC converters, inverters and inductive components in electric vehicles.

The polyurethane potting compound WEVOPUR 512 FLE supports the functionality of rapid shutdown boxes.

Rapid shutdown boxes are critical safety components in PV systems. A proven solution to ensure their reliable operation is the polyurethane potting compound WEVOPUR 512 FLE. The material effectively protects the boxes against moisture, corrosion and thermal stress.

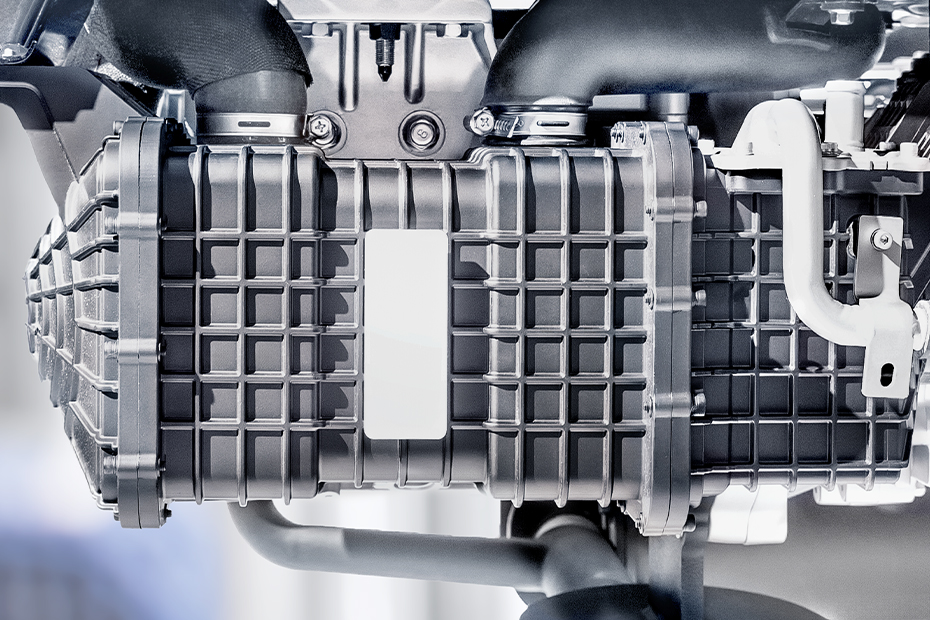

Adhesives and sealants for humidifiers support efficient and safe fuel cell systems.

Wevo-Chemie develops special adhesives, sealants and potting compounds for key components in modern hydrogen technologies. This includes material systems for humidifiers in PEM fuel cells, which are gas-tight, hydrolysis-resistant, ionic-pure and low in VOCs.

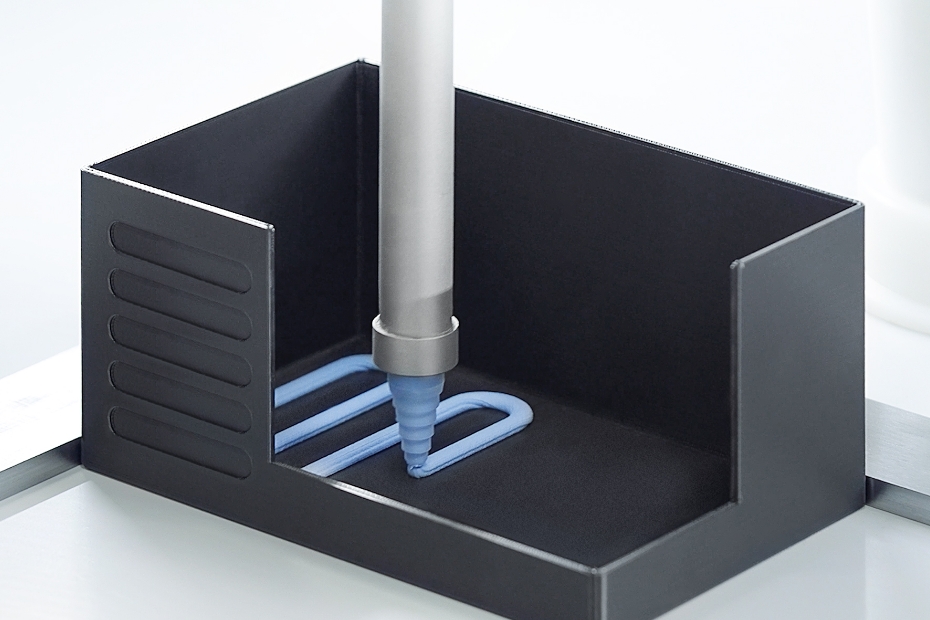

By direct application onto bipolar plates, Wevo’s LSR systems ensure reliable sealing of fuel cell stacks.

With WEVOSIL 23010 and 23030, Wevo expands its portfolio with liquid silicone rubbers for textile coatings and CIPG/FIPG sealing applications. The materials offer high elasticity, temperature resistance and reliable adhesion, while also ensuring efficient manufacturing processes.

In modern rail vehicles, transformer potting compounds from Wevo-Chemie ensure permanently safe power conversion.

Wevo-Chemie has developed specially optimised epoxy resin potting compounds for high-voltage transformers in rail vehicles. The thermally conductive materials provide partial discharge and cracking resistance as well as flame-retardant properties according to EN 45545-2. The result: reliable components for safe power conversion.

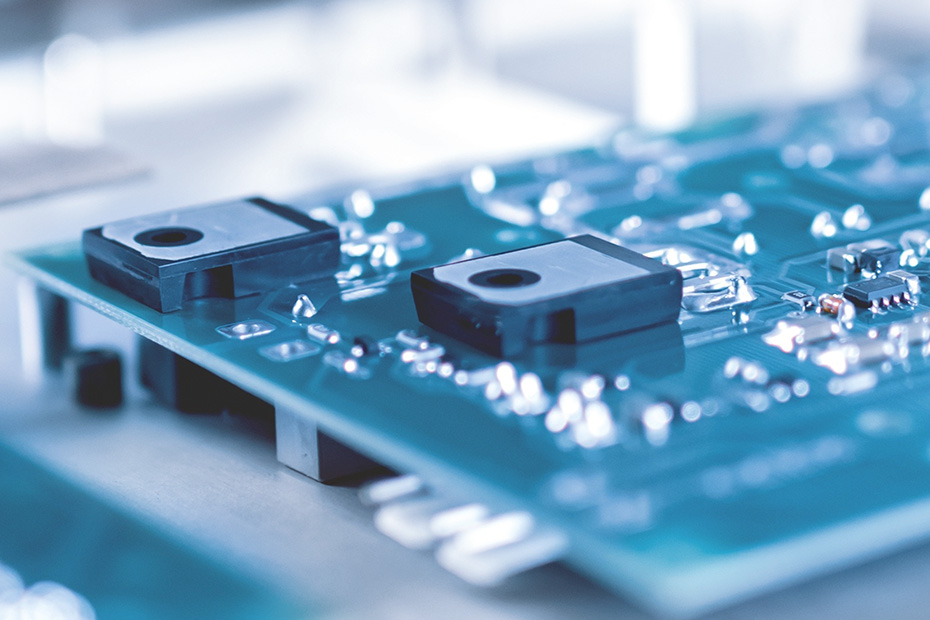

Wevo’s 2K silicone adhesive enables efficient production with adjustable pot life and curing.

Wevo-Chemie introduces a new structural adhesive designed to meet the demands of power electronics and EV batteries. WEVOSIL 28015 FL combines high thermal conductivity with structural strength and residual flexibility. In addition, this RTV silicone can be tailored for efficient production processes.

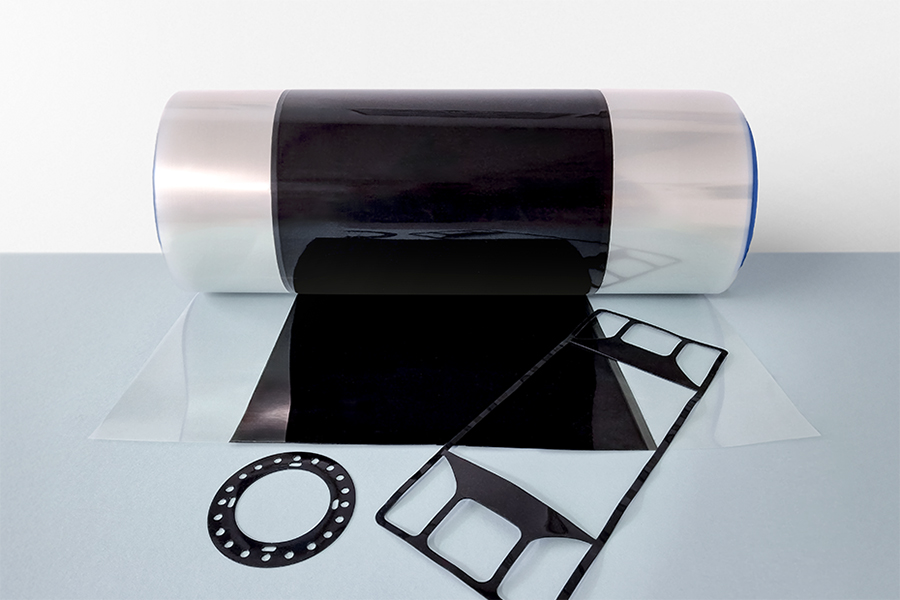

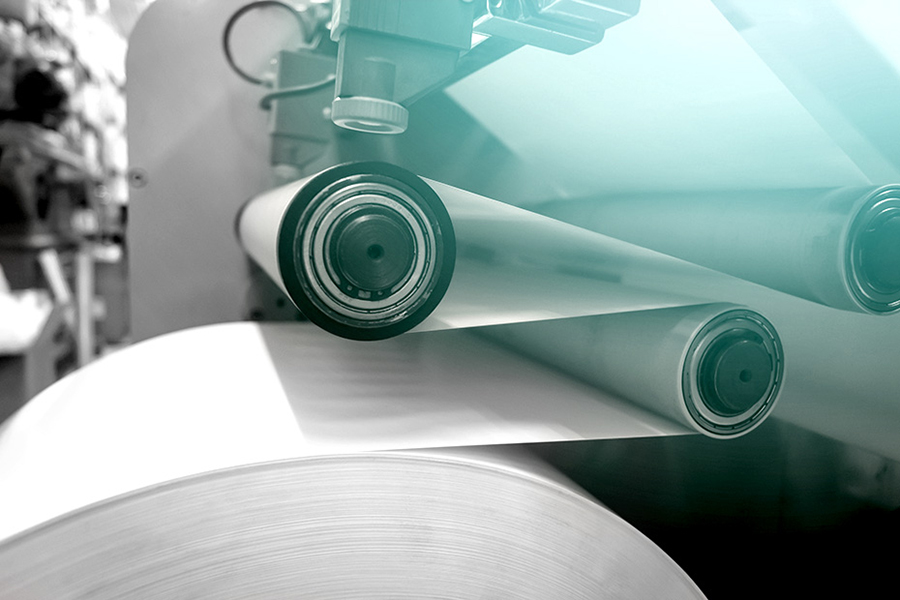

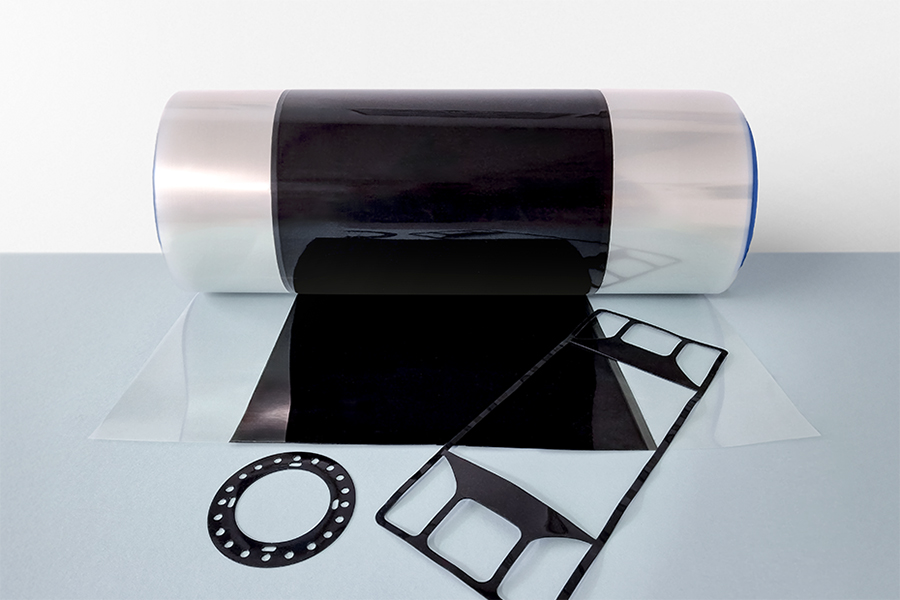

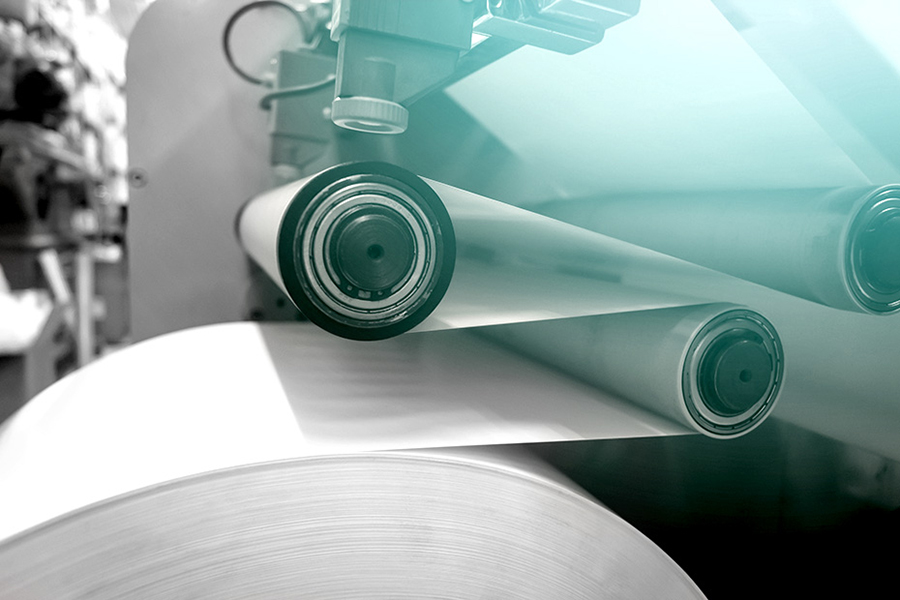

Carrier film coated with elastomer for flat hydrogen seals (Image source: Laufenberg GmbH).

Wevo-Chemie and Laufenberg present a process for continuous production of flat elastomer seals for fuel cells, electrolysers and redox-flow batteries. The roll-to-roll process allows customised layer thicknesses – ideal for automated, scalable production.

A new company from Wevo in Gurugram strengthens customer proximity and growth in India’s market for polyurethane solutions.

The establishment of WEVO Chemical India Private Limited marks an important step in the international growth strategy of the globally operating manufacturer of customised potting compounds, adhesives and sealants. The new company will build a nationwide sales structure and enable faster, more targeted customer support.

From power electronics to safety disconnects, Wevo’s silicone potting compounds provide tailored protection for durable components.

From power electronics to junction boxes, Wevo’s two-component potting compounds provide application-specific protection for safety-critical components in photovoltaic systems. The RTV silicones combine customisable thermal conductivity, high dielectric strength and UL 94 V-0 certified flame-retardant properties.

The potting compounds in the WEVOSIL 2210x series have been specifically optimised to ensure reliable silicone encapsulation.

With the WEVOSIL 2210x series, Wevo-Chemie expands its portfolio of silicone encapsulants. The super-soft potting compounds protect sensitive electronic components such as wire bonds and inductive parts, enable a reliable potting process, and offer selectable thermal conductivity.

Wevo’s WEVOPUR 512 FLE potting compound effectively protects PCBs against corrosion.

A proven potting casting resin from Wevo has demonstrated its effectiveness as corrosion protection for printed circuit boards: a study by Denmark Technical University showed numerous advantages compared to conventional conformal coatings. WEVOPUR 552 FLE enables significantly better resistance, especially when the PCBs are used in demanding applications.

The new Wevo silicone gels for electrical and electronic components offer a whole series of adaptable material properties.

The new RTV silicones from Wevo offer up to 50 per cent lower viscosity than comparable standard materials. What’s more, a whole series of material properties can be customised – for example, to ensure efficient and safe conditions both in production and during component operation.

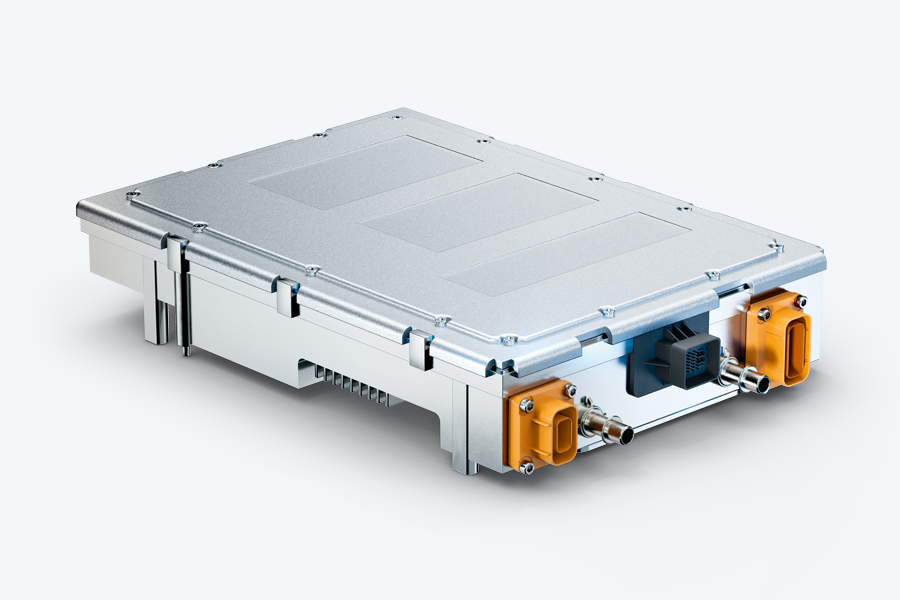

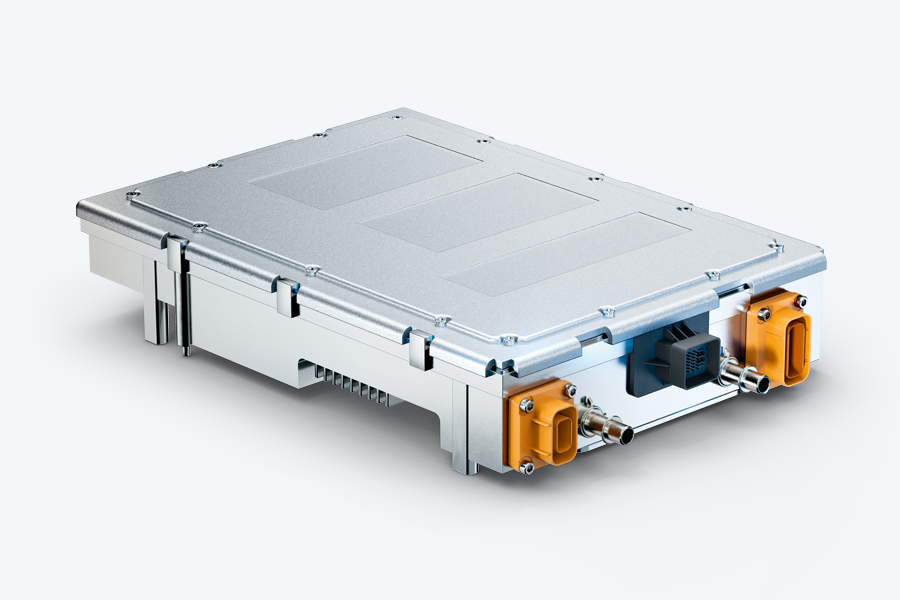

Wevo materials enable efficient thermal management for on-board chargers.

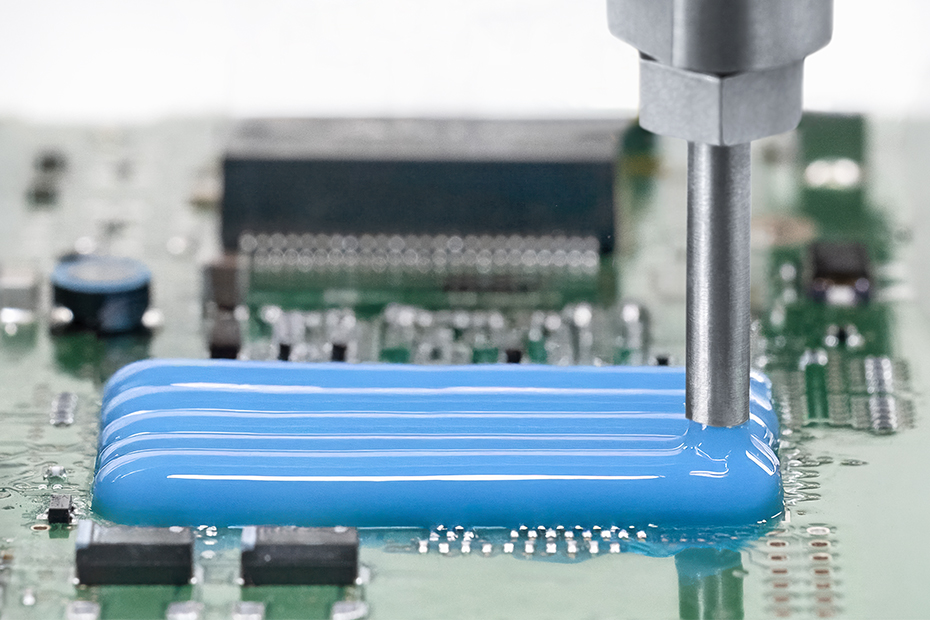

On-board chargers and DC/DC converters benefit from Wevo’s customised silicone potting compounds, gap fillers and silicone gels: in addition to the essential high thermal conductivity, these materials offer a whole series of customisable properties – from flow behaviour and pot life to hardness and basic adhesion.

The extensively modernised silicone production shop opens up new opportunities at Wevo’s headquarters near Stuttgart.

By expanding silicone production capacities at the headquarters in Ostfildern near Stuttgart, Wevo is taking an important step into the future. The company will thus be able to meet the growing demand for the customised gels, adhesives, gap fillers and potting compounds for use with modern electronic components.

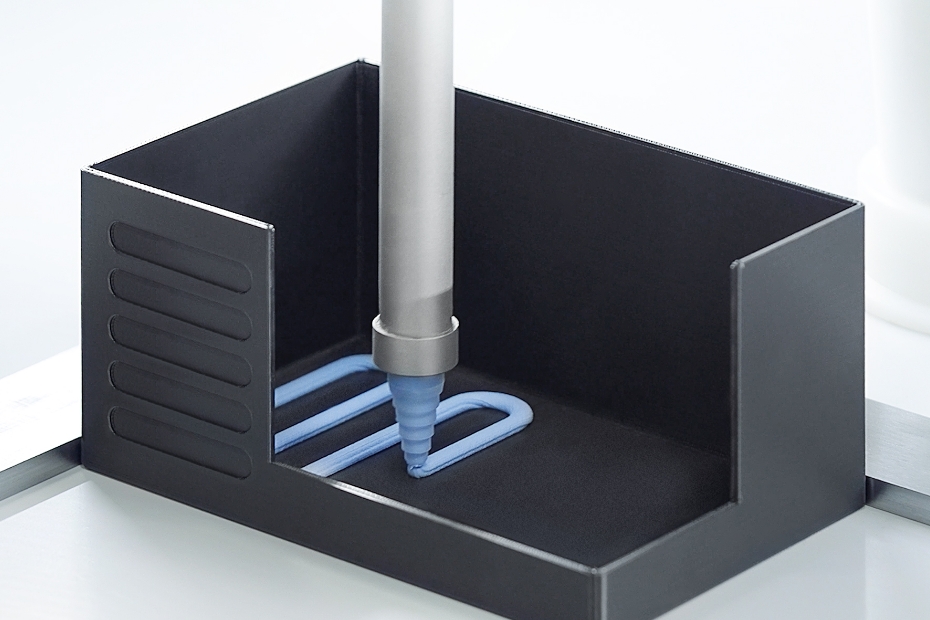

From battery technologies to power electronics, the new silicone gap filler from Wevo enables efficient thermal management.

With WEVOSIL 26040 FL, Wevo is launching an innovative, process- and application-optimised thermal interface material (TIM) designed to enhance the thermal management of electronic components. Its special properties make this gap filler the perfect solution – for battery technologies and power electronics.

Special polyurethanes from Wevo ensure that the batteries fitted in Lampuga’s electric surfboards operate safely and reliably over their entire lifespan.

Reliable protection is essential for electrical components used in water. Special polyurethane potting cpmpounds from Wevo guarantee long-term safe operation of the lithium-ion batteries used in Lampuga GmbH’s electric surfboards.

The new Zelu adhesive enables a significant increase in efficiency in upholstered furniture production.

The water-based 2-component contact adhesive from Zelu offers a number of advantages in the manufacture of upholstered furniture, including a significant improvement in efficiency thanks to single-sided application. In addition, its very high initial strength ensures a permanent bond between substrates, including ones with complex geometries.

Automated production of electrolysers is essential if the growing global demand for hydrogen is to be met.

Together with renowned research institutes and customers, Wevo has developed materials that enable the production process of electrolysers to be automated. To ensure reliable and long-term operation, the adhesives and sealants also offer high levels of chemical resistance, low hydrogen permeability and good adhesion properties.

Direct battery cooling offers crucial advantages for fast charging.

Immersion cooling is currently being researched as a potential cooling method for EV batteries. Wevo has launched highly chemical-resistant polyurethanes to ensure reliable sealing and the permanent prevention of leaks. These specially customised materials also facilitate efficient production.

The high temperatures which occur in the solar inverter have to be dissipated using specially adjusted materials.

Technological advances regarding solar inverters are also placing growing demands on the materials used. Wevo has responded by developing customised potting compounds and adhesives for the power electronics. Amongst other things, these provide the very high thermal conductivity that is increasingly required.

Automatically deploying, flush door handles require specially adjusted materials for the required sensors and antennas.

Reliable protection properties and good transmissibility for radio waves are just two of the requirements that sensors and antennas for keyless systems or automatically deploying exterior door handles place on potting compounds. Wevo polybutadienes that can be customised for specific applications support these functions and offer further advantages, too.

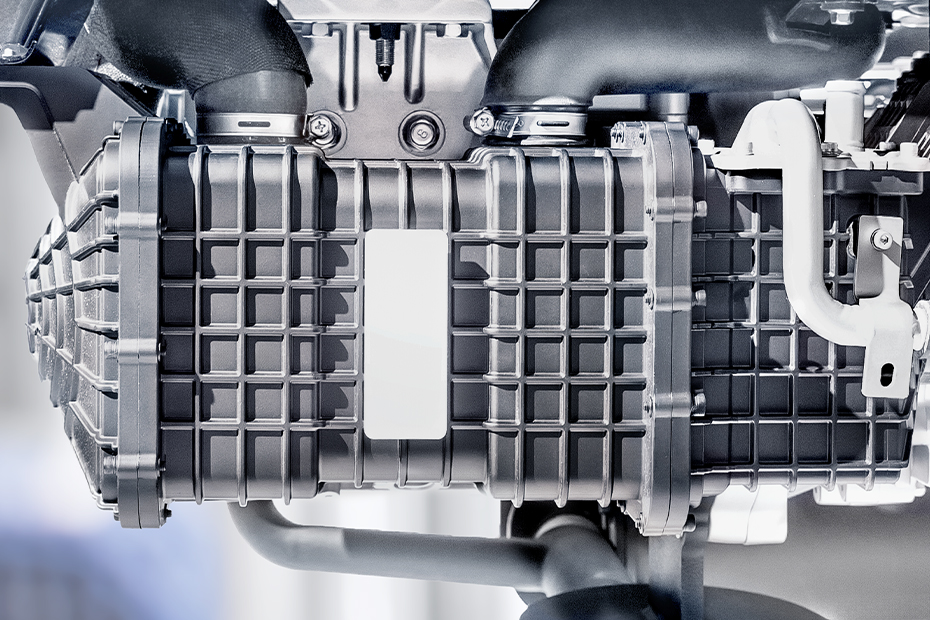

Customised potting compounds and gap fillers from Wevo enable efficient thermal management for modern inverters, for example.

Targeted thermal management is essential in inverters for electric vehicles. In addition to heat removal, customised potting compounds and gap fillers from Wevo also ensure the mechanical stability of the relevant components.

Customised potting compounds from Wevo support smart water management technologies.

Wevo materials based on polyurethane, epoxy resin and silicone enable smart and durable components for fields such as air quality control, water treatment and waste separation. Among other things, the potting compounds and adhesives protect electrical and electronic components against environmental conditions and mechanical stresses.

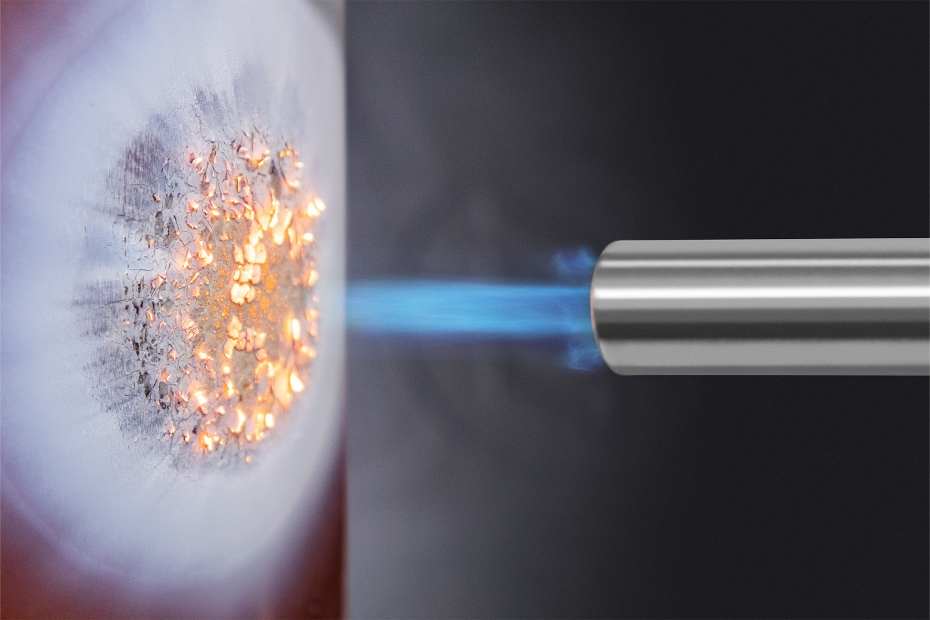

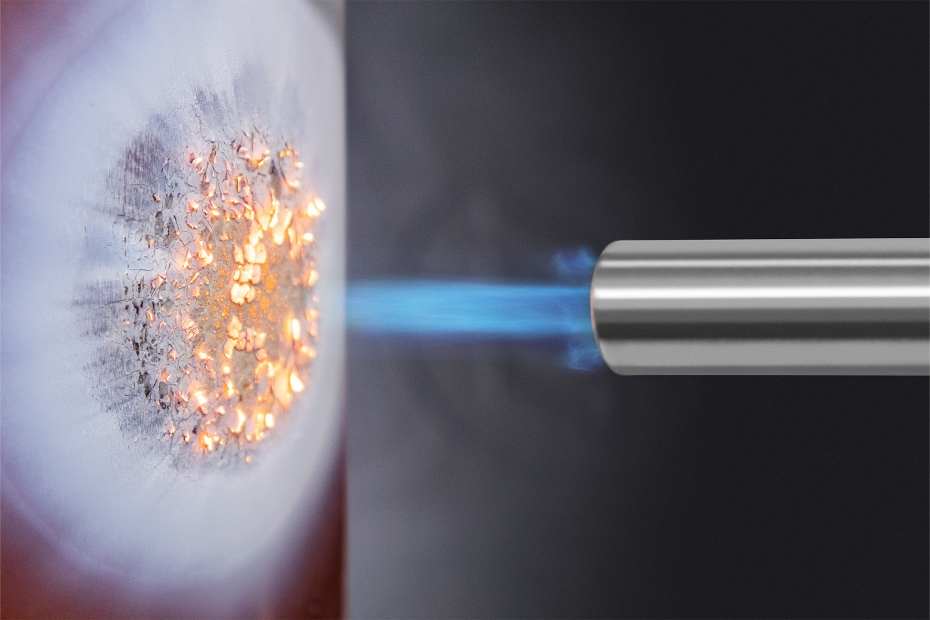

Among the advantages of Wevo silicones are their very high heat and flame resistance.

One of the most important requirements for batteries in electric vehicles is the ability to mitigate thermal runaway. Formulated especially for this purpose, Wevo silicones serve as efficient thermal, mechanical and electrical barriers while at the same time offering advantages over alternative materials.

The low gas permeability of Wevo’s silicones and polyurethanes has been confirmed in a study by ZBT, the Duisburg hydrogen and fuel cell centre.

The sealants and adhesives developed by Wevo for use in fuel cell stacks as well as in the surrounding system, referred to as the balance of plant, have been confirmed as having low hydrogen permeability in a study by the Duisburg hydrogen and fuel cell centre.

The first issue of Wevo’s SCIO magazine covers a diverse range of topics.

It tells stories and lets experts have their say. SCIO bridges the gap between global technological developments and economic issues – always with a positive view of the future and in search of new solutions and opportunities.

Wevo adhesive systems reliably dissipate the heat generated during the charging process from the battery cells to the heat sink.

They combine high thermal conductivity with a structural bonding option: if necessary, Wevo adhesive systems are applied to the cooling system in three dimensions and pressed directly together with the battery cells. This enables improved dissipation of the high temperatures generated during the charging process.

PSA adhesives for self-adhesive applications offer customisable solutions

With Curvalin D 409X, ZELU CHEMIE GmbH has a series of water-based pressure-sensitive adhesives with an already proven track record in its portfolio. The products in this series can be readily integrated into production processes and their various properties, such as the ability to debond and their tack, can be individually adapted.

Efficient thermal management is essential if high-performance electric drives are to be reliable.

Whether in local public transport, freight transport or agriculture, electric drives are becoming increasingly relevant. Efficient thermal management is crucial to prevent a loss of performance from these motors. To this end, Wevo has developed tailor-made products, which also facilitate short cycle times.

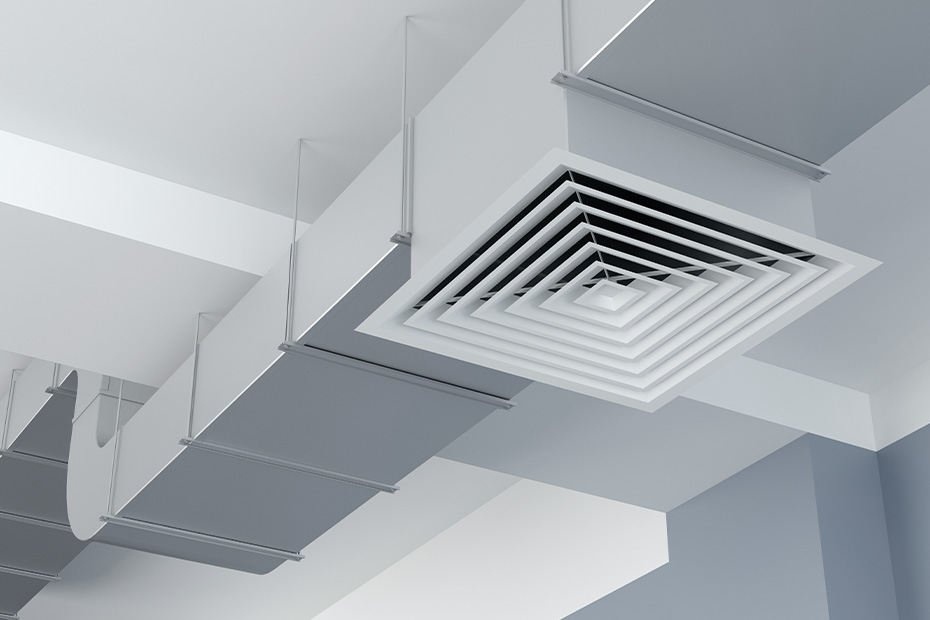

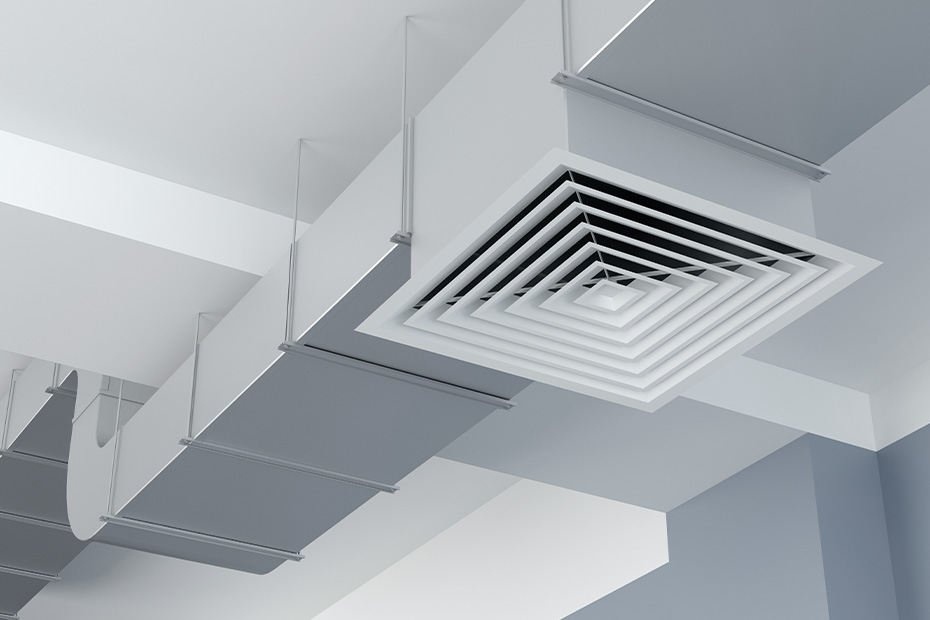

Modern ventilation systems make use of fans that need to be protected against various ambient conditions and the heat generated during operation.

Whether in medical, industrial or agricultural settings – fans are one of the key components in modern ventilation systems, wherever they are put to use. In order to protect the electronics as individually required and ensure targeted thermal management for the fan motors, Wevo-Chemie has developed potting compounds based on polyurethane and epoxy resin.